Pharma e-Symposium: Advancements in Drug Development and FormulationRegister

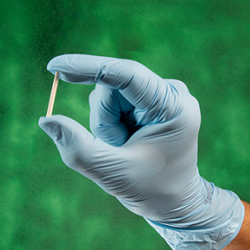

You will learn useful strategies regarding oral solid dosage (OSD) formulation, drug delivery systems, and implant development, as well as process R&D and manufacturing. In addition, the series covers several key techniques:

Register below by clicking on the link(s) to attend the sessions of interest to you; if registered, you will also receive a link to watch the recorded webinar. Each session is 45 minutes including 15 minutes for Q&A.

|